Corrugated

metal

hoses

come

in

many

configurations.

These

tools

can

help

ensure

you

select

the

right

corrugated

metal

hose

for

your

application.

There

are

many

components

in

a

metal

hose

assembly

and

care

should

be

taken

when

selecting

each

of

them.

Moreover,

the

components

have

their

own

unique

technical

limitations

so

it

is

important

to

make

sure

each

of

the

components

is

compatible

with

your

application.

In

much

the

same

way

as

a

“chain

is

as

strong

as

its

weakest

link”,

a

metal

hose

assembly

will

only

perform

to

the

limits

of

its

weakest

component.

Once

the

components

have

been

selected,

the

quality

and

skill

of

the

fabricator

assembling

the

components

becomes

important.

The

procedures

and

care

used

when

fabricating

assemblies

also

has

a

dramatic

effect

on

the

assembly’s

overall

performance.

Hose

Master

has

invested

a

considerable

amount

of

resources

to

researching

metal

hose

fabrication

and

developing

a

state-of-the-art

fabricating

center.

In

addition,

we

share

the

welding

technology

we

have

developed

with

our

fabricating

distributors.

All

of

this

is

done

to

promote

quality

and

consistency

in

fabricating

metal

hose

assemblies.

In

this

section,

we

will

discuss

the

various

components

that

make

up

a

corrugated

metal

hose

assembly,

and

what

information

a

metal

hose

fabricator

will

need

in

order

to

make

an

assembly

for

your

application.

If

you

need

assistance

determining

the

information,

we

have

also

included

an

explanation

of

how

to

analyze

the

application

and

make

the

appropriate

selections.

Specifying

a

Corrugated

Metal

Hose

Assembly:

In

order

to

make

an

assembly,

the

fabricator

will

need

answers

to

the

following

five

questions.

For

more

information

about

any

of

these

questions,

or

for

a

list

of

available

options,

click

the

topic

heading

for

a

more

detailed

explanation.

-

Hose (type,

alloy,

and

size)

-

End

Fittings (type,

alloy,

and

size

for

each

end)

-

Length

of

the

assembly (either

overall

length

or

live

length)

-

Fabrication

options

-

Accessories

If

you

have

the

answers

to

these

questions,

a

metal

hose

fabricator

will

be

able

to

make

the

assembly.

If

you

do

not

know

the

answers

to

all

five

questions,

you

will

need

to

obtain

them.

The

next

section

is

designed

to

help

you

determine

the

answers.

Analyzing

an

Application:

To

properly

design

a

metal

hose

assembly

for

a

particular

application,

the

following

design

parameters

must

be

determined.

To

help

remember

them,

they

have

been

arranged

to

form

the

acronym

“S.T.A.M.P.E.D.”

-

Size –

The

diameter

of

the

connections

in

which

the

assembly

will

be

installed

is

needed

to

provide

a

proper

fit.

This

information

is

required.

-

Temperature –

As

the

temperature

to

which

the

assembly

is

exposed

(internally

and

externally)

increases,

the

strength

of

the

assembly’s

components

decreases.

Also,

the

coldest

temperature

to

which

the

hose

will

be

exposed

can

affect

the

assembly

procedure

and/or

fitting

materials.

If

you

do

not

provide

this

information

it

will

be

assumed

that

the

temperatures

are

70°

F.

-

Application –

This

refers

to

the

configuration

in

which

the

assembly

is

installed.

This

includes

both

the

dimensions

of

the

assembly

as

well

as

the

details

of

any

movement

that

the

assembly

will

experience.

This

information

is

necessary

to

calculate

assembly

length

and

required

flexibility.

-

Media –

Identify

all

chemicals

to

which

the

assembly

will

be

exposed,

both

internally

and

externally.

This

is

important

since

you

must

be

sure

that

the

assembly’s

components

are

chemically

compatible

with

the

media

going

through

the

hose

as

well

as

the

environment

in

which

the

hose

is

installed.

If

no

media

are

given,

it

will

be

assumed

that

both

the

media

and

the

external

environment

are

compatible

with

all

of

the

available

materials

for

each

component.

-

Pressure –

Identify

the

internal

pressure

to

which

the

assembly

will

be

exposed.

Also,

determine

if

the

pressure

is

constant

or

if

there

are

cycles

or

spikes.

This

information

is

important

to

determine

if

the

assembly

is

strong

enough

for

the

application.

If

no

pressure

is

given

it

will

be

assumed

that

the

pressure

is

low

and

there

are

no

pressure

surges

or

spikes.

-

End

Fittings –

Identify

the

necessary

end

fittings.

This

is

required

since

fittings

for

the

assembly

must

be

chosen

to

properly

fit

the

mating

connections.

-

Dynamics

–

Identify

the

velocity

at

which

the

media

will

flow

through

the

assembly.

Since

corrugated

metal

hose

does

not

have

a

smooth

interior,

rapid

media

flow

can

set

up

a

resonant

frequency

that

will

cause

the

hose

to

vibrate

and

prematurely

fail.

If

no

velocity

is

given,

it

will

be

assumed

that

the

velocity

is

not

fast

enough

to

affect

the

assembly’s

performance.

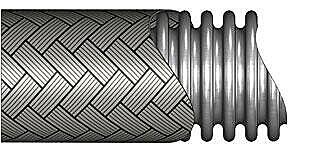

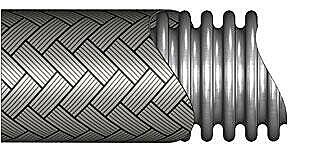

Stress-Lite CorrugaTed Metal Hose

Discover the Power of Stress-Lite™

When it comes to manufacturing corrugated metal hose, minimizing residual stress during the formation of corrugations is crucial. Hose Master has revolutionized this process with its Stress-Lite™ technology, featuring Hydroforming and Crimpforming methods.

Why Choose Stress-Lite™?

Unlike other methods that induce excessive residual stress and potentially shorten the product's lifespan, Stress-Lite™ employs proprietary gentle forming technologies. These processes eliminate the twisting of the tube that often leads to harmful torsional stress, fatigue, and premature failure.

The Innovation Behind Stress-Lite™

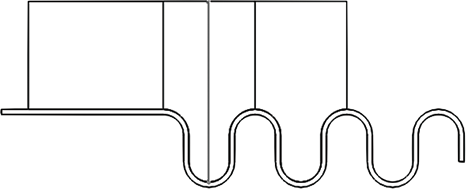

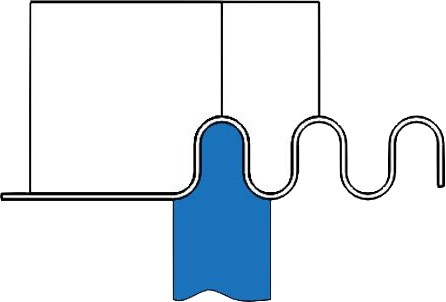

Stress-Lite™ annular hose processes synchronize non-torsional radial forming with simultaneous bi-directional axial tube feed. This advanced technique results in hoses with:

- Minimal Work Hardening

- Uniform Wall Thickness

- No Residual Torsional Stress (RTS)

Experience Exceptional Performance

With Stress-Lite™, you benefit from:

- Greater Flexibility

- Higher Cycle Life

Choose Stress-Lite™ for superior performance and reliability in your metal hose applications.

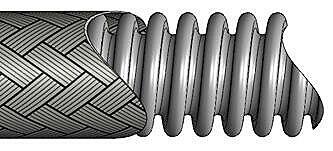

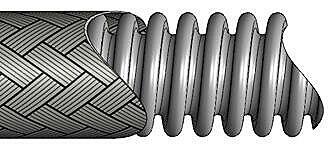

Processes of Manufacturing:

Crimpforming vs Hydroforming

-

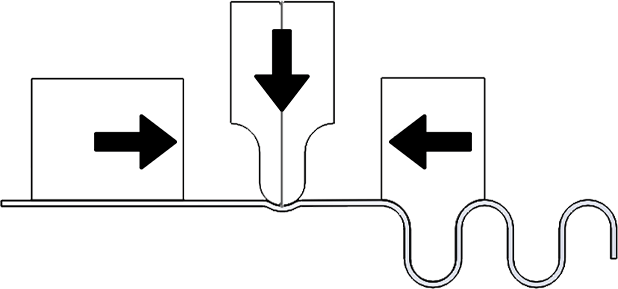

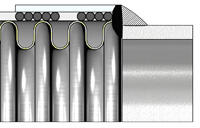

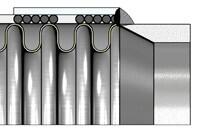

Crimpforming Process

Crimpforming method grabs a section of tube, compresses it without torsion using a “shutter-crimp”, while simultaneously feeding the tube in axially from both directions.

-

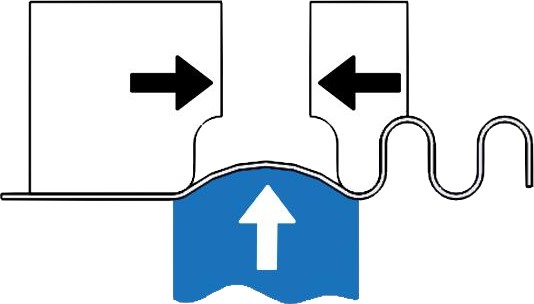

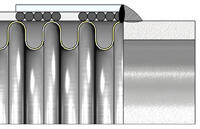

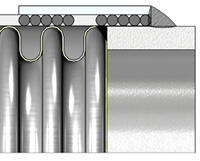

Hydroforming Process

Hydroforming method grabs a section of tube, expands it without torsion using high pressure water, while simultaneously feeding the tube in axially from both directions.

-

Crimpforming Process

Crimpforming compresses the tube from the outside, and is used on more ridged tube having a larger t/d (tube thickness to diameter) ratio.

-

Hydroforming Process

Hydroforming expands the tube from the inside.

Our engineers at Hose Master have developed Stress-Lite™ processes which represent the state-of-the-art technology in hose manufacturing. This, in conjunction with an optimized hose profile, yields the best corrugated metal hose in the industry.

Stress-Lite™ Products

-

Is the standard of Hose Master’s extensive line of high performance Stress-Lite™ annular corrugated stainless steel hose. Proprietary technology ensures the excellent cycle life of the hose, with minimum effort to flex or bend the hose.

-

Hose Master’s close pitch metal hose. It is manufactured using the same high quality process used to make Annuflex hose, but the number of corrugations per foot is increased to allow for greater flexibility.

-

Hose Master’s high-pressure, annular corrugated metal hose. Pressureflex HP® is made from heavy-wall stainless steel, and offers flexibility and dependability when higher pressures are a factor.

-

Hose Master’s annular, heavy-wall corrugated metal hose, designed for ULTRA high-pressure applications. PressureMax HP® offers superior flexibility and is made from heavy wall T321 or T316L stainless steel.

-

Hose Master’s chemical transfer hose. Chemking™ offers excellent corrosion resistance to many of the most severe applications found in chemical processing.

-

Hose Master’s 276 alloy, corrugated chlorine-transfer assembly, designed to meet the demands of this application. With considerations made for both wet and dry chlorine, these assemblies are the safest available.

-

Has the “stay-put” characteristics required for stress-free connections between piping systems and rotary joints or other similar static applications.

-

Heavy-duty corrugated hose designed for use in applications that require a bronze hose.

-

Hose Master’s T321 spirally-welded, helical corrugated hose specifically designed to achieve extreme flexibility while maintaining good pressure ratings. The helical design facilitates draining and reduces in-line turbulence.

-

Hose Master’s T316 double-walled, spirally-welded corrugated metal hose. Specially designed to maintain extreme pressure and flexibility, Hydraflex™ is self-draining and generates minimal in-line turbulence.

Fittings

Metal

hose

is

more

versatile

than

other

hose

in

that

virtually

any

fitting

can

be

attached

to

metal

hose.

Other

types

of

hose

require

special

shanks

and

collars

in

order

to

attach

fittings.

For

metal

hose,

any

fitting

made

from

a

weldable

material

can

be

attached

without

the

need

for

special

features.

This

versatility

also

means

that

multiple

fittings

can

be

welded

together

to

make

custom

solutions

for

difficult

applications.

Selecting

the

proper

fittings

for

an

application

is

largely

determined

by

the

mating

fittings

to

which

the

hose

assembly

will

be

attached.

Once

the

mating

fittings

have

been

identified,

the

hose

fittings

should

complement

the

mating

fittings

in

type,

size,

and

alloy.

Even

though

the

selection

of

hose

fittings

is

determined

by

the

mating

fittings,

it

is

a

good

idea

to

confirm

that

the

fittings

used

in

the

application

are

appropriate

for

the

application

and

any

necessary

changes

made.

Ensure

that

the

fittings

are

chemically

compatible

with

and

are

able

to

withstand

the

pressure

and

temperatures

of

both

the

media

and

the

surrounding

environment.

The

following

show

commonly

used

fittings

for

corrugated

metal

hose

assemblies.

Please contact Hose

Master’s

Customer

Service

Department

for

end

connections

that

are

not

listed.

-

Male Pipe Nipple

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, 276

- Sizes – 1/8″ thru 8″

- Schedules – 40 and 80

-

Hex Male

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, Brass

- Sizes – 1/4″ thru 4″

-

Grooved-End Fitting

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1″ thru 8″

- Schedule – 40

-

LiveLink® Swivel Fitting

- Alloys – T304 Stainless Steel

- Sizes – 1/4″ thru 2″

-

Female Union (Threaded/Socket Weld)

- Alloys – T304 & T316 Stainless Steel, Carbon Steel, Malleable Iron, Brass

- Sizes – 1/4″ thru 4″

- Class – 125#, 150# (3000# Carbon Steel Only)

-

Female Half Coupling (Threaded/Socket Weld)

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1/4″ thru 4″

- Class – 150# (3000#)

-

1, 2, or 3 Piece SAE (JIC)

- Alloys – T316 Stainless Steel, Carbon Steel, Brass (nut only)

- Sizes – 1/4″ thru 2″

-

45° and 90° SAE (JIC)

- Alloys – Stainless Steel, Carbon Steel

- Sizes – 1/2″ thru 2″

-

Sanitary Flange

- Alloys – T304 and T316 Stainless Steel

- Sizes – 1″ thru 3″

-

Slip-on Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1/2″ thru 12″

- Class – 150#, 300#

-

Plate Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1/2″ thru 12″

- Class – 150#

-

Weld Neck Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1/2″ thru 6″

- Class – 150#, 300#

-

TTMA Flange

- Alloys – T316 Stainless Steel, Carbon Steel

- Sizes – 2″ thru 6″

-

C Stub with Floating Flange

- Alloys – T304 and T316 Stainless Steel

- Sizes – 1/2″ thru 10″

- Schedule – 10

-

A Stub with Lap Joint Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, 276

- Sizes – 1/2″ thru 8″

- Schedules – 10, 40

-

TTMC C Stub Swivel

- Alloys – T304 and T316 Stainless Steel

- Sizes – 4″ thru 6″

- Schedule – 10

-

Part A and Part D (Cam-Lock)

- Alloys – T316 Stainless Steel, Brass, Aluminum

- Sizes – 1/2″ thru 8″

-

Tube End

- Alloys – T304, T316, and T321 Stainless Steel, Carbon Steel

- Sizes – 1/8″ thru 8″ (seamless and welded)

- Wall Thickness – various

-

Short and Long Radius Elbows (45° and 90°)

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, 276

- Sizes – 1/4″ thru 6″

-

Reducer

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 3/4″ thru 6″

- Schedule – 10 (40 Carbon Steel)

-

Beveled Pipe End

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, 276

- Sizes – 1/8″ thru 8″

- Schedules – Various

-

Ground Joint Female

- Alloys – Carbon Steel

- Sizes – 1/2″ thru 4″

-

Specialty Gas Nuts

- Alloys – Brass

- Sizes – A, B, C, D

- Thread Type – SAE and BSP

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

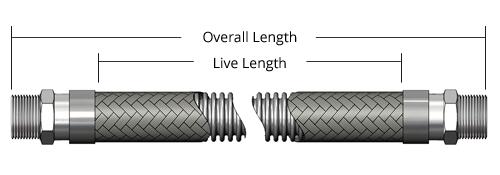

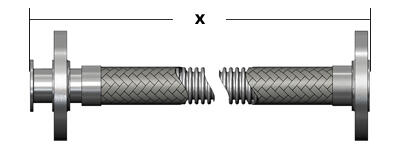

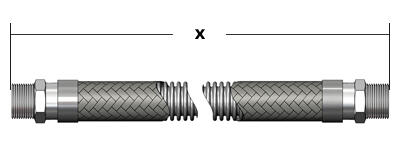

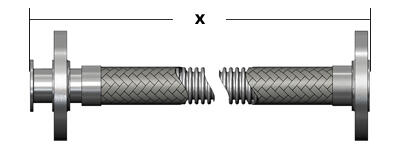

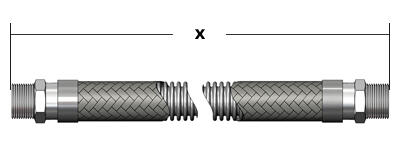

To

calculate

the

proper

length

of

a

hose

assembly:

-

Verify

that

the

installation

is

properly

designed

You

can

see

our illustration of

the

right

and

wrong

ways

to

install

a

hose

assembly.

Basically,

there

are

three

considerations:

-

Do

not

torque

the

hose.

-

Do

not

overbend

the

hose.

-

Do

not

compress

the

hose.

-

Calculate

the

live

length

of

the

assembly

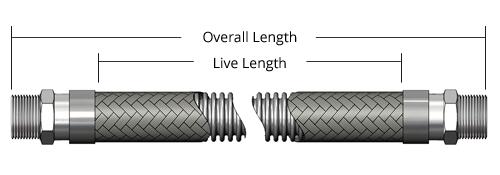

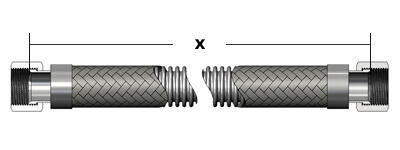

The

live

length

of

the

assembly

is

the

amount

of

active

(flexible)

hose

in

an

assembly;

that

is,

the

hose

between

the

braid

collars.

See

the Length

Calculation chart

for

more

information.

-

Calculate

the

overall

length

of

an

assembly

Overall

length

is

equal

to

the

live

length

plus

the

lengths

of

the

braid

collars

and

fittings.

When

adding

fitting

lengths

be

aware

that

the

points

from

which

measurements

should

be

taken

vary

for

different

fitting

types.

When

calculating

overall

length

for

assemblies

with

threaded

fittings,

remember

to

account

for

the

length

of

thread

that

is

lost

by

threading

into

the

mating

connection.

See

the Thread

Allowance chart

for

more

information.

-

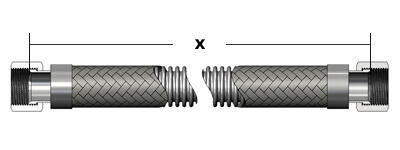

JIC/SAE

type

fittings

are

measured

from

the

seat

of

the

fitting.

-

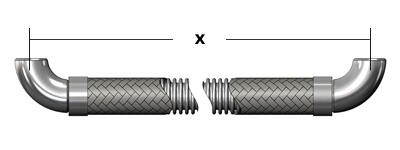

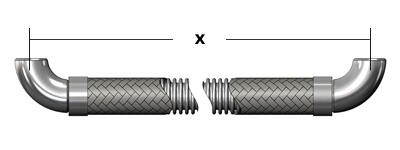

Elbows

and

other

fittings

with

a

radius

are

measured

from

the

centerline

of

the

fitting.

-

Flanges

are

measured

from

the

flange

face

or

from

the

face

of

the

stub

end

if

one

is

used.

-

Threaded

fittings

are

measured

to

the

end

of

the

fitting.

Hose

Master

places

emphasis

on

continual

improvements

within

our

manufacturing

processes,

product

offering

and

services.

Hose

Master

reserves

the

right

to

make

changes

without

further

notice

to

any

products

contained

herein.

Fabrication

Options

Corrugated

metal

hose

is

used

in

a

very

broad

spectrum

of

applications.

Just

as

the

hose,

fittings,

and

other

assembly

parts

must

be

tailored

to

suit

the

demands

of

the

service,

so

must

the

methods

of

joining

these

components.

While

standard

production

joining

methods

work

very

well

for

the

majority

of

service

demands,

the

following

extremes

may

dictate

special

joining

or

fabrication

techniques:

-

Pressures

-

Temperatures

-

Corrosion

-

Other

conditions

Hose

Master

has

developed

specialized

welding,

brazing,

joining,

and

fabrication

procedures

to

assure

the

integrity

and

serviceability

of

metal

hose

assemblies

in

even

the

most

extreme

applications.

The

fabrication

options

to

be

considered

are:

-

Specialized

attachment

techniques

-

Testing

options

-

Additional

cleaning

requirements

-

Packaging

In

each

of

the

following

sections,

the

standard

method

and

available

options

are

explained.

Select

the

options

best

suited

for

your

application.

Specialized Attachment Techniques

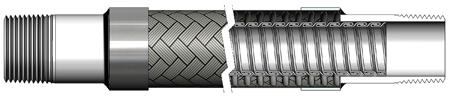

Industry Standard

This method will be used unless another method is specified

Standard fabrication of an assembly generally consists of:

- Cutting the hose and braid through a hose corrugation valley.

- Installation of a braid collar over each end of the hose.

- Trimming of any excess braid.

- “Cap” welding the hose, braid, and braid collar together.

- Cleaning the cap weld surface.

- Placement and alignment of a fitting on the cap weld.

- “Attachment” welding the fitting to the cap weld.

- Silver brazing is also available. Consult factory.

Half-Corrugation

Standard fabrication sometimes leaves a portion of the cut corrugation, or corrugation “lip”, just under the base of the fitting. In specialized applications this residual lip may not be desirable. To prevent any exposed corrugation edges from causing damage, the hose can be specially prepared for welding by cutting the corrugation on the crest, rather than in the valley, thereby removing the lip.

Smooth Transition Weld

For applications in which corrosion is a concern, all crevices and fissures must be minimized. Specialized hose and fitting preparation, in conjunction with proprietary welding techniques, is available to provide a full penetration hose-to-fitting weld that is smooth and crevice free.

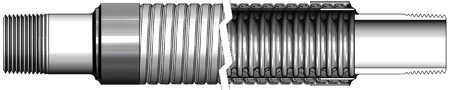

Braid-Over Construction

Assemblies operating at the upper limits of their rated working pressure or in severe service may benefit from a braid-over construction. The fitting is first welded to the unbraided hose. Then a special metal reinforcing ring is installed over the fitting and next to the weld. Finally the braid is drawn over the end of the hose and the ring, and welded to the side of the fitting. This technique reduces the amount of heat introduced into the braid wires, nearly eliminates the heat effected zones of the cap and attachment welds, and maximizes the wire strength. Braid-over construction may also be used for specific high cycle applications.

Testing Options

Note: Always test an assembly with a medium that has a smaller molecular or atomic size than the service required.

Standard Leak Testing

Every corrugated hose assembly is leak tested prior to shipment. Standard testing consists of pressurizing the assembly with air and then submerging the entire assembly under water. This method is reliable and sufficient for the majority of applications.

Hydrostatic Testing

While the standard test is designed to detect leaks, hydrostatic testing is designed to test the assembly’s strength. Testing of an assembly to its full permissible test pressure can be economically and accurately accomplished by filling the assembly with liquid while concurrently evacuating all air. The assembly is then hydrostatically pressurized using high pressure pumps. The test pressure is maintained for a predetermined period of time.

High Pressure Gas

Testing with air under water, at pressures of up to 2500 psi, is available for specialized applications. For a more sensitive test, the use of gases such as nitrogen or helium can be requested.

Dye Penetrant

Dye penetrant testing is available for both leak and for weld bead inspection, in accordance with Hose Master procedures or to customer specified standards.

Helium Mass Spectrometer

This is the most sensitive leak detection method generally available. The standard test method is to attach the assembly to a mass spectrometer and generate a very high vacuum in the assembly. The exterior of the assembly is then flooded with helium. The relatively tiny helium atoms penetrate even very small openings and are drawn into the mass spectrometer where they are detected and the leak size quantified. Helium Mass Spectrometer testing can be modified to satisfy customer or regulatory agency requirements.

Additional Cleaning Requirements

The hydroforming method of corrugated hose manufacturing inherently yields a very clean product. However, specialized cleaning for specific applications is available upon request. Contact Hose Master’s Customer Service Department for details.

Packaging

All assemblies are shipped with protectors over sealing surfaces such as threads and flange faces. Spacer bars are installed on all shorter double-flanged assemblies to prevent compression of the assembly during shipping and handling. Special packaging is available to suit customer requirements, including crating, plastic bagging, labeling, and custom fitting protectors.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

Accessories

Metal

hose

assemblies

often

require

special

accessories

or

components

in

order

to

provide

long

service

life

in

severe

applications

or

make

the

assemblies

easier

to

use.

There

are

many

accessories

that

may

be

specified

including:

-

Guard,

made

from

metal

and

other

materials,

can

be

provided

to

protect

an

assembly

from

overbending,

abrasion,

impact,

and

thermal

damage.

-

Jacket

and

tracer

hoses

are

incorporated

into

corrugated

hose

assemblies

in

order

to

keep

certain

media

at

elevated

or

reduced

temperatures

so

that

it

can

be

easily

conveyed.

-

A

sacrificial

bronze

braid

can

be

inserted

between

the

hose

and

the

stainless

steel

braid

to

improve

cycle

life.

One

or

several

accessories

can

be

easily

combined

with

an

assembly

to

more

efficiently

transport

media,

protect

the

assembly,

or

both.

The

following

pages

list

some

common

accessories

along

with

a

brief

explanation

of

the

benefits

each

accessory

offers.

This

is

not

an

exhaustive

list

of

all

possible

accessories.

Please

contact

Hose

Master’s Customer

Service

Department with

your

specific

requirements.

Spring Guard

When there is potential for damaging an assembly in service, a guard can be easily installed during fabrication. This type of guard consists of a metal spring that is attached behind the fitting. The style of guard can be tailored to meet the application and the type of hose.

Protective Cover

If the potential for impact or high temperature damage is not severe, or if the additional weight and bulk of a full metal guard is unacceptable, rubber or plastic scuff guards can be installed to protect the corrugated hose and braid.

Insulating Jackets

If the corrugated hose is to convey hot media, and there is a potential for skin contact, an insulated, protective jacket is available. The jacket consists of a tubular banded fiberglass insulation, covered and impregnated with silicone rubber. The jacket is installed over the corrugated hose and metal banded in place. The jacket can also be used to insulate the corrugated assembly and either prevent ambient heat from being conveyed to the media or to reduce heat loss.

Tagging

A variety of tags and identifications can be affixed to assemblies. These include cardboard, plastic, and metal tags. Serial numbers, application information, assembly performance capabilities, and other customer specific information can be provided either on tags or permanently engraved onto one or both braid collars.

Certifications

Standard written certifications for materials or inspections can be supplied for corrugated hose or assemblies. Certifications of conformance to specific customer requirements such as military certifications are also available.

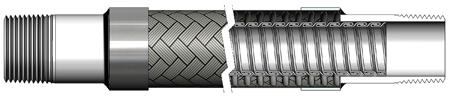

Liners

An interlocked hose or liner is often installed inside a corrugated hose assembly. The liner commonly serves two additional purposes, while still maintaining the full working pressure of the corrugated hose. The first is to protect the hose corrugations from excessive media velocities. Media speeds can induce resonant vibrations in the corrugations causing rapid fatigue and subsequent fracturing of the hose wall. The liner provides a relatively smooth surface for the media and, by avoiding the media impacting on the corrugation valleys, reduces the chances of harmonic resonance. The second purpose for a liner is for abrasion resistance. Even slightly abrasive media flowing at medium to high speeds can cause premature wear of the corrugated hose interior surfaces. The liner provides a smooth flow path as well as a relatively thick layer of abrasion resistant metal between the media and the corrugated hose. The liner will also help reduce pressure loss due to friction between the media and corrugated hose. Proper fit between the hoses is essential for good performance. Because Hose Master makes both the corrugated hose and liners, perfect fit is assured. See the Velocity in Metal Hose chart for more information.

Armor Guard / Bend Restricter

Applications in which the corrugated hose is subject to external abrasion, molten material splash, or impact damage may require a protective armor or guard along all or a portion of its length. A guard is typically made from interlocked or squarelocked metal hose and is welded to the assembly. Note that the bend restricter has a bend diameter equal to or greater than the corrugated hose it is protecting.

Jacketed Assemblies

A jacketed assembly consists of a “hose within a hose.” An inner or primary media conveying hose is enclosed or jacketed by a larger diameter hose. The hoses are joined at each end by specially designed fittings so that there is no media pathway between the two hoses. Jacketed assemblies are often specified when the primary media must be kept at either an elevated or cryogenic temperature. Steam is often circulated through the jacket hose to keep a viscous material in the inner hose hot and easily conveyed. A vacuum can also be pulled on the jacket hose to insulate cryogenic liquids being conveyed in the inner hose.

Tracers

Traced assemblies are similar in concept to jacketed assemblies in that there is an inner, smaller diameter hose encased by a single larger diameter hose. Where jacketed assemblies surround the media with heat or cold, traced assemblies have the media surround the hose containing the heating or cooling element. The tracer, or inner hose, may also be installed in a long “U” shaped loop within the outer hose, with the steam inlet and outlet at the same end of the assembly.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.