Stripwound

metal

hoses

come

in

many

configurations.

These

tools

can

help

ensure

you

select

the

right

stripwound

metal

hose

for

your

application.

Care

should

be

taken

when

specifying

a

stripwound

hose

assembly.

Each

of

the

components

can

have

a

dramatic

effect

on

the

assembly’s

performance.

In

addition

to

carefully

selecting

components,

the

way

they

are

assembled

is

also

very

important.

Hose

Master

has

developed

fabrication

techniques

that

help

maximize

the

assembly’s

performance.

Two

of

these

techniques

are

square

cutting

the

hose

ends

and

welding

on

the

inside

of

the

fittings.

The

stripwound

profile

is

helical.

When

it

is

cut

by

traditional

methods,

the

hose

end

will

also

be

helical.

This

creates

a

gap

between

the

fitting

and

the

end

of

the

hose.

This

gap

can

cause

the

fittings

to

separate

from

the

hose

during

use.

Square

cutting

ensures

that

the

hose

end

and

the

fitting

are

flush,

leaving

no

gaps.

If

the

fittings

are

welded

on

the

hose,

welding

the

inside

provides

for

a

smooth

transition

between

hose

and

fittings,

preventing

product

from

becoming

damaged.

Specifying

a

Stripwound

Hose

Assembly:

Designing

a

stripwound

hose

assembly

requires

the

determination

of

five

factors:

-

Hose (type,

alloy,

and

size)

-

End

fittings (type,

alloy,

and

size

for

each

end)

-

Assembly

length

-

Fabrication

options

-

Accessories

If

these

factors

have

been

determined,

a

fabricator

will

be

able

to

make

the

assembly.

If

not,

these

questions

may

be

answered

by

proceeding

to

the

next

section.

Analyzing

an

Application:

To

properly

design

a

metal

hose

assembly

for

a

particular

application,

the

following

design

parameters

must

be

determined.

To

help

remember

them,

they

have

been

arranged

to

form

the

acronym

“S.T.A.M.P.E.D.”

-

Size –

The

diameter

of

the

connections

in

which

the

assembly

will

be

installed

is

needed

to

provide

a

proper

fit.

This

information

is

required.

-

Temperature –

As

the

temperature

to

which

the

assembly

is

exposed

(internally

and

externally)

increases,

the

strength

of

the

assembly’s

components

decreases.

If

you

do

not

provide

this

information

it

will

be

assumed

that

the

temperatures

are

70

deg

F.

-

Application –

This

refers

to

the

configuration

in

which

the

assembly

is

installed.

This

includes

the

dimensions

into

which

the

assembly

must

fit

as

well

as

the

details

of

any

movement

that

the

assembly

will

experience.

This

is

required

since

you

cannot

determine

the

proper

length

or

proper

hose

type

without

it.

-

Media –

Identify

all

chemicals

to

which

the

assembly

will

be

exposed,

both

internally

and

externally.

This

is

important

since

you

must

be

sure

that

the

assembly’s

components

are

chemically

compatible

with

the

media.

If

no

media

is

given,

it

will

be

assumed

that

both

the

media

and

environment

are

compatible

with

all

of

the

available

materials

for

each

component.

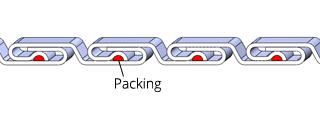

-

Pressure –

Identify

the

internal

pressure

to

which

the

assembly

will

be

exposed.

Stripwound

metal

hose,

by

the

nature

of

its

construction,

is

not

pressure

tight.

However,

pressure

and

media

infiltration

through

the

stripwound

wall

can

be

minimized

by

the

insertion

of

one

of

a

variety

of

packings

into

the

wall

during

hose

manufacturing.

If

no

pressure

is

given

it

will

be

assumed

that

there

is

no

pressure.

-

End

Fittings –

Identify

the

necessary

fittings.

This

is

required

since

fittings

for

the

assembly

must

be

chosen

to

properly

fit

the

mating

connections.

-

Dynamics –

Identify

the

velocity

at

which

the

media

will

flow

through

the

assembly.

Extremely

high

flow

or

abrasive

media

can

cause

premature

failure.

If

no

velocity

is

given,

it

will

be

assumed

that

the

velocity

is

not

fast

enough

to

affect

the

assembly’s

performance.

Hose

Master

places

emphasis

on

continual

improvements

within

our

manufacturing

processes,

product

offering

and

services.

Hose

Master

reserves

the

right

to

make

changes

without

further

notice

to

any

products

contained

herein.

Stripwound

metal

hose

is

a

rugged

product

made

from

a

strip

of

steel

that

is

profiled

and

continuously

wound

around

a

mandrel

to

form

a

hose.

Hose

Master’s

proprietary

manufacturing

process

yields

an

extremely

consistent

and

balanced

profile

that

maximizes

strength

and

flexibility.

Stripwound

hose

is

used

as

a

guard,

exhaust

hose,

and

for

the

transfer

of

dry

bulk

materials.

Types of Stripwound Metal Hose Products

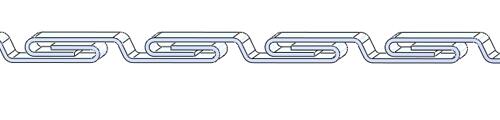

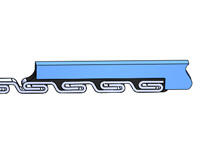

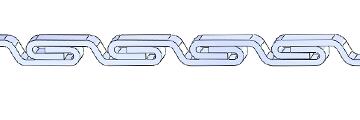

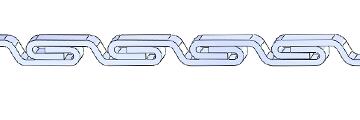

Roughbore Interlocked

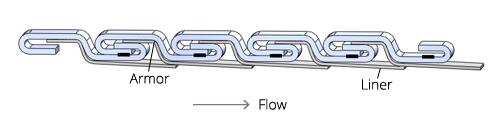

The strip is formed with legs that interlock to form a hose that is flexible and ideally suited for conveying dry bulk materials, gas exhaust, or used as a protective cover.

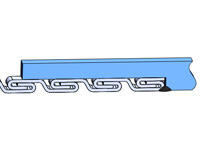

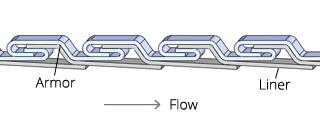

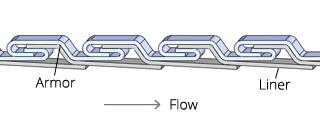

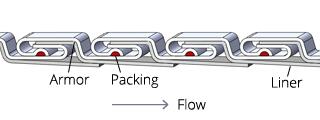

Smoothbore Interlocked

Designed to reduce damage to delicate materials, another steel strip is added inside a roughbore hose to provide a smooth interior surface. Smoothbore hose is also flexible and used for dry bulk conveying.

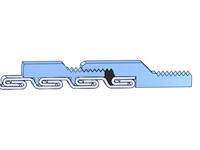

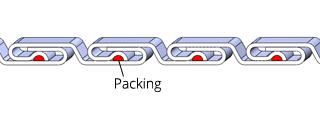

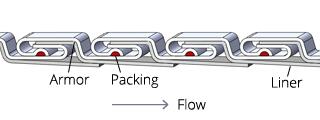

Packed Interlocked

Packing may be added to interlocked hose to minimize leakage through the hose profile.The most effective packings are made from resilient materials such as elastomers and, to a lesser extent, cotton. Harder materials (stainless steel and copper) are also available if requested.

Roughbore

Smoothbore

Torque-Resistant Interlocked

Designed for torque resistance and enhanced sealability, this product resists twisting, unwinding, and strip flare-up after cutting. Torque-resistant hose is manufactured in either roughbore or smoothbore constructions.

Roughbore

.jpg)

Smoothbore

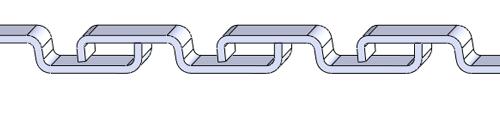

Floppy Interlocked

Designed to offer flexibility, strength, and crush-resistance, this product is used for casing or armor of small diameter hose and electrical cables.

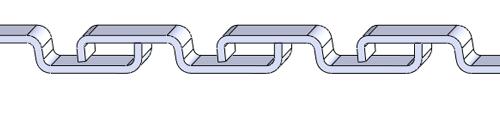

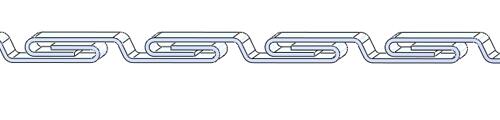

Floppy Squarelocked

The strip is formed into square shapes that are locked together. Squarelocked is flexible and is primarily used as a protective covering for wires, fiber optic cables, and other hoses.

Now that you know more about the options, browse our online selection of stripwound metal hoses.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

Selecting

the

proper

fittings

for

an

application

is

largely

determined

by

the

mating

fittings

to

which

the

hose

assembly

will

be

attached.

Once

the

mating

fittings

have

been

identified,

the

hose

fittings

should

complement

the

mating

fittings

in

type,

size

and

alloy.

Even

though

the

selection

of

hose

fittings

is

determined

by

the

mating

fittings,

it

is

a

good

idea

to

confirm

that

the

fittings

used

in

the

application

are

appropriate

for

the

application

and

any

necessary

changes

made.

Ensure

that

the

fittings

are

chemically

compatible

with

and

are

able

to

withstand

the

conditions

in

which

the

hose

is

installed

and

in

which

it

will

be

used.

The

following

show

commonly

used

fittings

for

stripwound

metal

hose

assemblies.

Please contact Hose

Master’s

Customer

Service

Department

for

end

connections

that

are

not

listed.

-

Male Pipe Nipple

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, Aluminum

- Sizes – 1 1/2″ thru 8″

- Schedules – 40, 80

-

Grooved-End Fitting

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 8″

-

Slip-on Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 12″

- Class – 150#, 300#

-

Plate Flange

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 14″

- Class – 150#

-

C Stub with Floating Flange

- Alloys – T304 and T316 Stainless Steel

- Sizes – 1 1/2″ thru 10″

- Schedule – 10

-

Part A and Part D (Cam-Lock)

- Alloys – T316 Stainless Steel, Carbon Steel, Aluminum

- Sizes – 1 1/2″ thru 8″

-

Tube End

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 8″

- Wall Thickness – Various

-

Reducer

- Alloys – T304 and T316 Stainless Steel, Carbon Steel

- Sizes – 1 1/2″ thru 6″

- Schedule – 10, 40 (Carbon Steel)

-

Beveled Pipe End

- Alloys – T304 and T316 Stainless Steel, Carbon Steel, Aluminum

- Sizes – 1 1/2″ thru 8″

- Schedules – Various

-

NPSM Female or Male

- Alloy – T304 Stainless Steel

- Sizes – 4″ thru 6″

-

Tar and Asphalt Male and Female

- Alloys – Malleable Iron

- Sizes – 1 1/2″ thru 4″

-

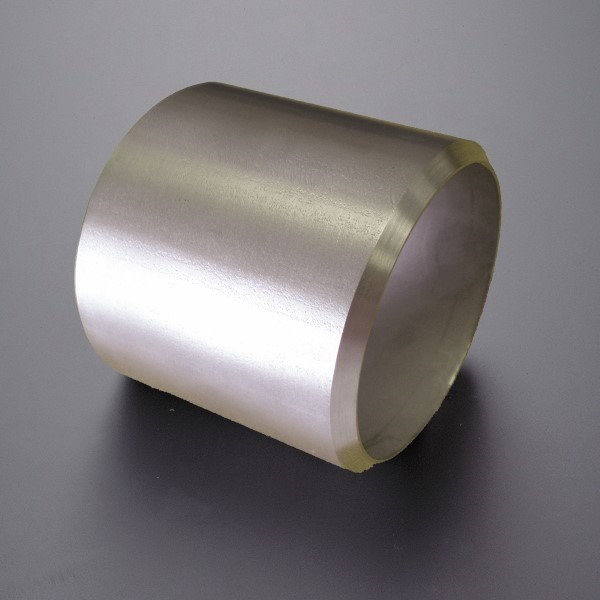

Compensator

- Alloys – Urethane

- Sizes – 3″ thru 6″

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

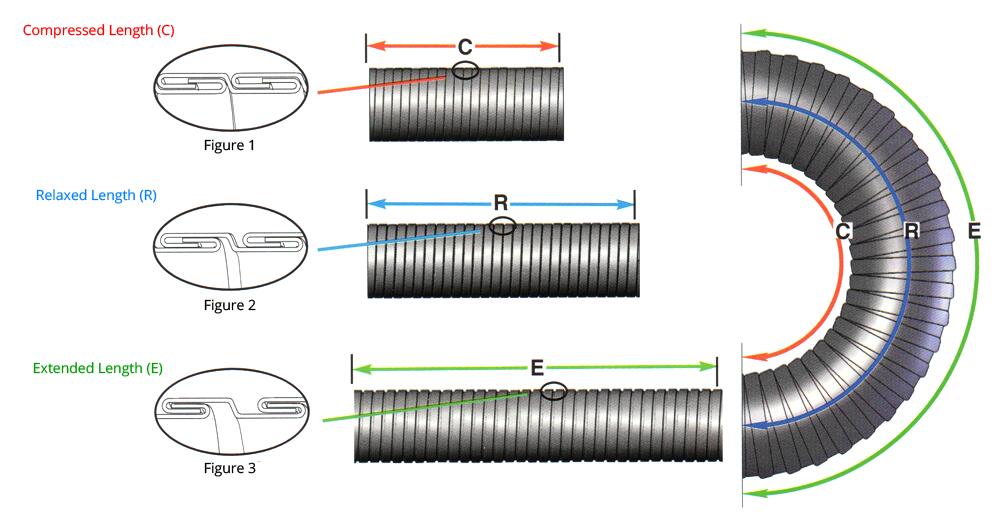

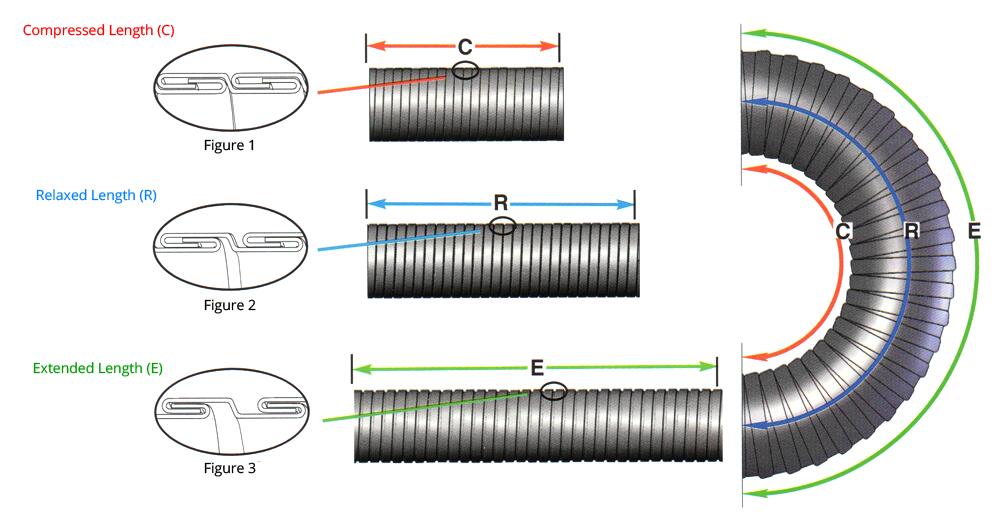

Various

States

of

Hose

Length

Interlocked

metal

hose

can

be

Compressed

(Figure

1)

and

Extended

(Figure

3),

and

it

is

this

ability

that

allows

the

hose

to

bend.

The

Relaxed

Length

(R)

is

defined

as

the

average

between

the

Extended

Length

(E)

and

the

Compressed

Length

(C)

of

the

hose

(Figure

2),

and

is

calculated

as R=1/2

(C+E).

When

interlocked

hose

is

bent

as

far

as

it

can

go,

the

outside

surface

of

the

hose

is

in

the

Extended

state,

while

the

inside

surface

is

in

the

Compressed

state.

Measuring

Various

Hose

States

The

Relaxation

Factor

is

defined

as

Extended

Length

(E)

divided

by

Relaxed

Length

(R)

and

is

used

to

facilitate

ordering

interlocked

hose.

Hose

Master

can

provide

the

Relaxation

Factor

for

each

of

our

interlocked

hose

products.

Interlocked

metal

hose

is

generally

priced

and

defined

in

its

extended

state.

Frequently,

the

hose

designer

thinks

in

terms

of

the

relaxed

state.

This

is

especially

true

when

using

smoothbore

hose,

packed

hose,

and

calculating

assembly

length.

In

these

cases,

the

purchaser

must

define

the

state

(relaxed)

when

placing

an

order,

OR

multiply

the

desired

(relaxed)

length

by

its

Relaxation

Factor

to

order

it

as

an

extended

length.

Example: For

a

hose

with

a

relaxation

factor

of

1.12

To

obtain

a

20-foot

relaxed

length

of

hose,

it

can

be

ordered

as

22.4

feet

of

extended

product

(20’

x

1.12).

Additionally,

if

this

extended

length

of

hose

weighs

3

lbs.

per

foot,

and

costs

$4.00

per

foot,

then

in

the

relaxed

state

it

will

weigh

3.36

lbs.

per

foot

(3

lbs.

per

foot

x

1.12)

and

it

will

cost

$4.48

per

foot

($4.00

per

foot

x

1.12).

Hose

Master

places

emphasis

on

continual

improvements

within

our

manufacturing

processes,

product

offering

and

services.

Hose

Master

reserves

the

right

to

make

changes

without

further

notice

to

any

products

contained

herein.

Fabrication

Options

Interlocked

metal

hose

is

used

in

a

variety

of

applications.

Just

as

the

hose,

fittings,

and

other

assembly

parts

must

be

tailored

to

suit

the

demands

of

the

service,

so

must

the

methods

of

joining

these

components.

Hose

Master

has

developed

specialized

fabrication

procedures

to

assure

the

integrity

and

serviceability

of

metal

hose

assemblies

in

even

the

most

extreme

applications.

The

following

page

identifies

each

of

these

methods

and

gives

a

brief

explanation

under

what

circumstances

each

should

be

considered.

Epoxy

Fittings may be attached to interlocked hose using a 2-part epoxy. An epoxied fitting-to-hose connection, made with properly prepared fittings, can be as strong or stronger than the hose itself at service temperatures up to 200°F. Epoxy is recommended for packed interlocked hose to avoid damaging the packing material. Epoxy also affords a convenient method for field attachment of a variety of fittings to interlocked hose.

Welding/Brazing

Welding provides the strongest possible connection between the hose and fittings. Whenever possible, the weld is made on the interior, or I.D., hose-to-fitting joint in order to provide a smooth surface over which the media flows. Welding is generally not recommended for packed interlocked hose, as the packing may be damaged by the high welding temperature.

I.D./O.D.

If the fittings are welded to the hose, welding the I.D. provides for a smooth transition between hose and fittings, preventing product from becoming damaged. Also, welding the O.D. of the fitting prevents exterior contamination from entering the crevice while providing additional strength.

Mechanical Attachment

Certain high temperature applications requiring interlock hose, particularly Tar and Asphalt service, require a fitting that actually threads and locks onto the hose corrugations. A high temperature packing is used to seal against leakage. These fittings are leak tight up to 400°F and are easily field attached.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

Stripwound

hose

assemblies

often

require

special

accessories

or

components.

Accessories

may

be

used

to

improve

performance

or

to

make

the

assembly

easier

to

use.

The

following

pages

list

some

common

accessories

along

with

a

brief

explanation

of

the

benefits

each

accessory

offers.

This

is

not

an

exhaustive

list

of

all

possible

accessories.

Please

contact

Hose

Master’s

Customer

Service

Department

if

you

would

like

an

accessory

not

listed.

Lay Line

A straight, painted line can be applied to interlocked hose along its entire length. This lay line serves to give clear warning to the user if the hose is being potentially damaged from torque or twisting in service. Monitoring torsion or twisting of the assembly can significantly increase the service life of the hose.

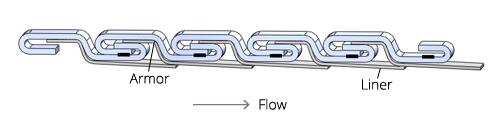

Flow Arrows

Smoothbore interlocked hose is unidirectional in that the overlapping liner strip affords a smooth surface in one direction. Media flow in the opposite direction can easily cause damage to both the hose and to abrasion sensitive media, such as plastic pellets. Flow arrows are painted on all smoothbore hose to indicate the correct flow direction. In specific high-velocity applications, the flow direction can also become a factor in roughbore interlock hose. Flow arrows can be provided on roughbore hose upon customer request.

Square Cutting

If the hose service requires a smooth transition from the hose to the fittings, the end of the hose must fit flush against the fitting shoulder. The only way to provide this kind of fit between hose and fitting is to square cut the end of the hose.

Braid

For higher than normal working pressures, or for critical safety situations, a stainless steel braid can be installed and welded over a stripwound hose assembly. The braid serves to prevent the hose from overextending and damaging the hose wall.

Tagging

A variety of tags and identifications can be affixed to assemblies. These include cardboard, plastic, and metal tags. Serial numbers, application information, assembly performance capabilities, and other customer specific information can be provided either on tags or permanently engraved onto one or both braid collars.

Certifications

Standard written certifications for materials or inspections can be supplied for corrugated hose or assemblies. Certifications of conformance to specific customer requirements such as military certifications are also available.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

.jpg)