Petroleum Flex Connectors Dos and Don'ts

Keeping Industry Flowing

Petroleum Flex Connectors Dos and Don'ts

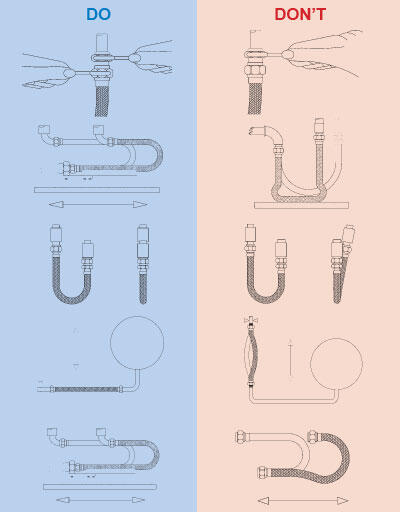

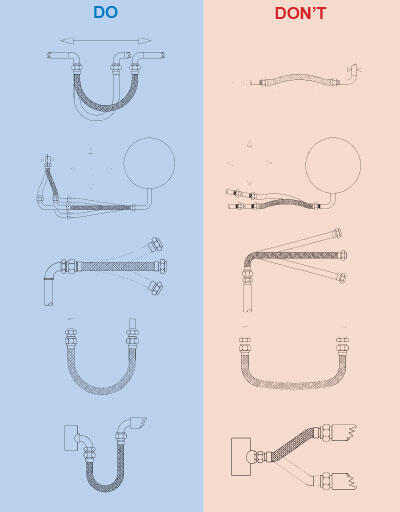

- DO design the installation to allow for all movement (ground, vibration, etc.) after the installation.

- DO keep the hose free from all objects and debris.

- DO measure to ensure proper length of connector has been selected.

- DO handle and store the connectors carefully before an installation.

- DO follow all printed instructions included with the connectors.

- DO note the minimum bend radius as specified.

- DO install flexible connectors so that the bend is as close to the center of the connector as possible.

- DO keep the painted lay line straight and on the centerline of the connector.

- DO use a wrench only on the hex flats.

- DO use the manufacturer’s recommended cathodic protection system or dielectric isolation boot.

- DO check for leaks before covering the installation.

- DON'T use a wrench or any other tool on the hose or braid collar.

- DON'T twist or torque the flex connector.

- DON'T over-bend a flexible connector beyond its minimum bend radius.

- DON'T install a flexible connector with the bend next to the end fittings.

- DON'T attempt to stretch or compress a flexible connector to fit an installation, or allow connector to stretch or compress during use.

- DON'T restrict flexibility by allowing a connector to come into contact with other components or equipment during an installation or during use.

- DON'T expose connector to damage or corrosives during storage, installation or use. Groundwater, road salt, soil, etc. are or may contain corrosives. If necessary use a cover or boot to protect the connector.

- DON'T attempt to reuse a flex connector once it has been installed.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

-

When to Use Flexible Metal Products

-

Select the Right Hose for Your Application

-

Select the Right Corrugated Metal Hose

-

Select the Right Stripwound Metal Hose