Data Centers

Why Do Metal Hoses Matter in Data Centers? > Minimized Downtime

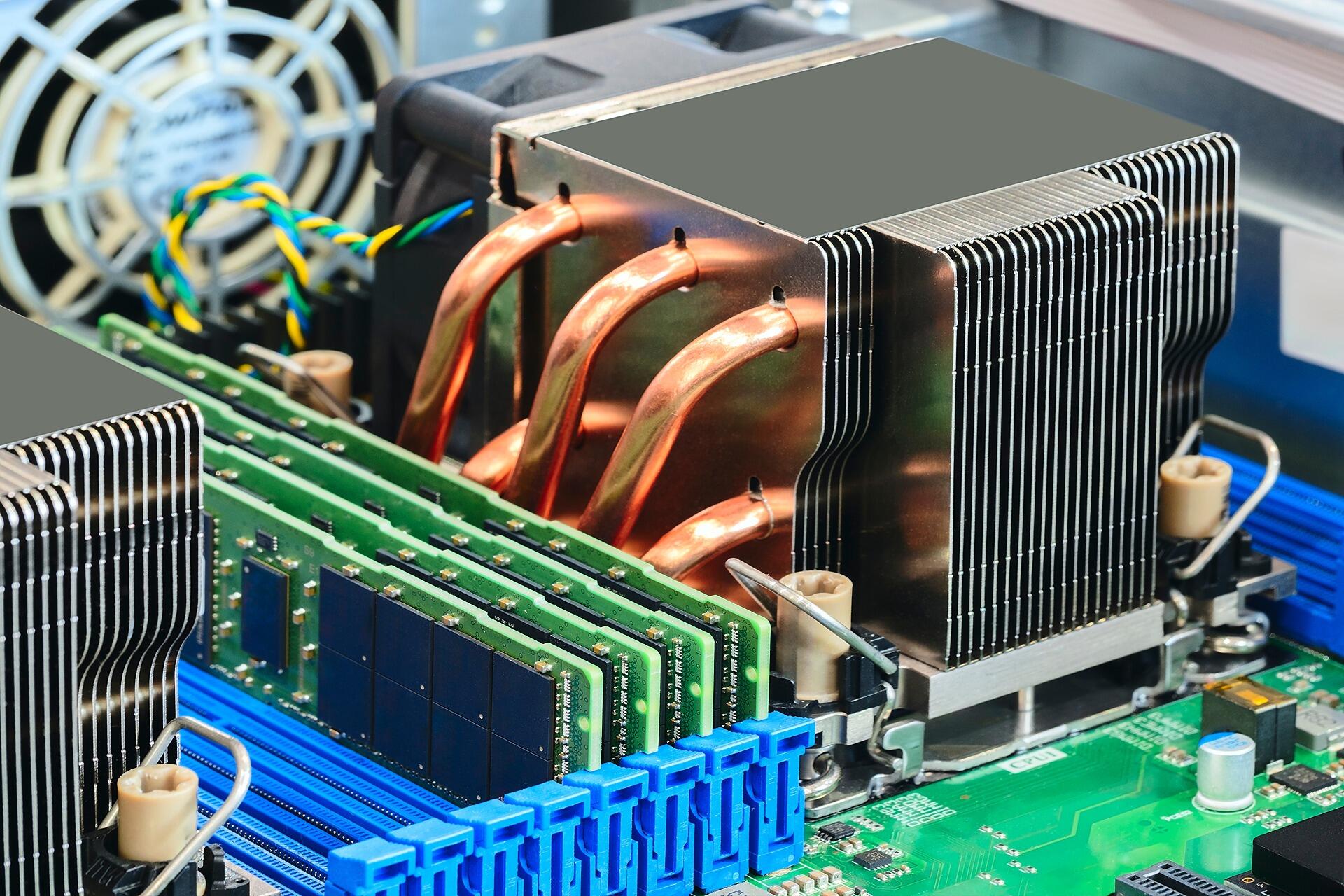

As in any mission-critical industry, downtime is very costly and unacceptable. The market continues to push the boundaries for high-performance computing and is increasingly shifting towards liquid cooling to maximize efficiency. The performance and durability of these cooling systems is critical in minimizing facility downtime. This is why metal hoses are a preferred choice in data center cooling systems:

Non-metal hose alternatives are subject to fittings ejections, leaks, and fire risk. Metal hose assemblies eliminate all of these potential hazards with permanent, leak-tight welded ends and a non-flammable construction.

Hose Master offers passivation and pickling of metal hose assemblies to remove contaminants and minimize potential sites for corrosion and permeation.

The flexibility of Hose Master’s metal hoses makes installation and maintenance effortless, saving both time and effort. Cooling system configurations are subject to changes and Hose Master’s metal hoses take this into account, without sacrificing safety.

Metal hoses can withstand extreme temperatures and pressures and have extended cycle life in comparison to non-metal alternatives.

Product Spotlight:

Masterflex is an excellent choice well-suited for hyperscale data center cooling applications.

- Close pitch: Increased flexibility for ease of use and necessary maintenance.

- Fire-proof: A fully stainless steel construction reduces the risk of a fire.

- High-pressure tolerance: External braid makes the hose ideal for demanding applications.

Liquid Cooling Applications:

- Manifolds

- Cold Plates

- Coolant Distribution Units (CDUs)

- Immersion Cooling

- Rear Door Heat Exchangers

Hose Master Advantage:

The Hose Master Advantage delivers engineered metal hose assemblies across the U.S. for data center applications, providing superior flexibility, corrosion resistance, fire safety, and leak tight performance for long term reliability under demanding thermal and pressure conditions.

-

When to Use Flexible Metal Products

-

Select the Right Hose for Your Application

-

Select the Right Corrugated Metal Hose

-

Select the Right Stripwound Metal Hose